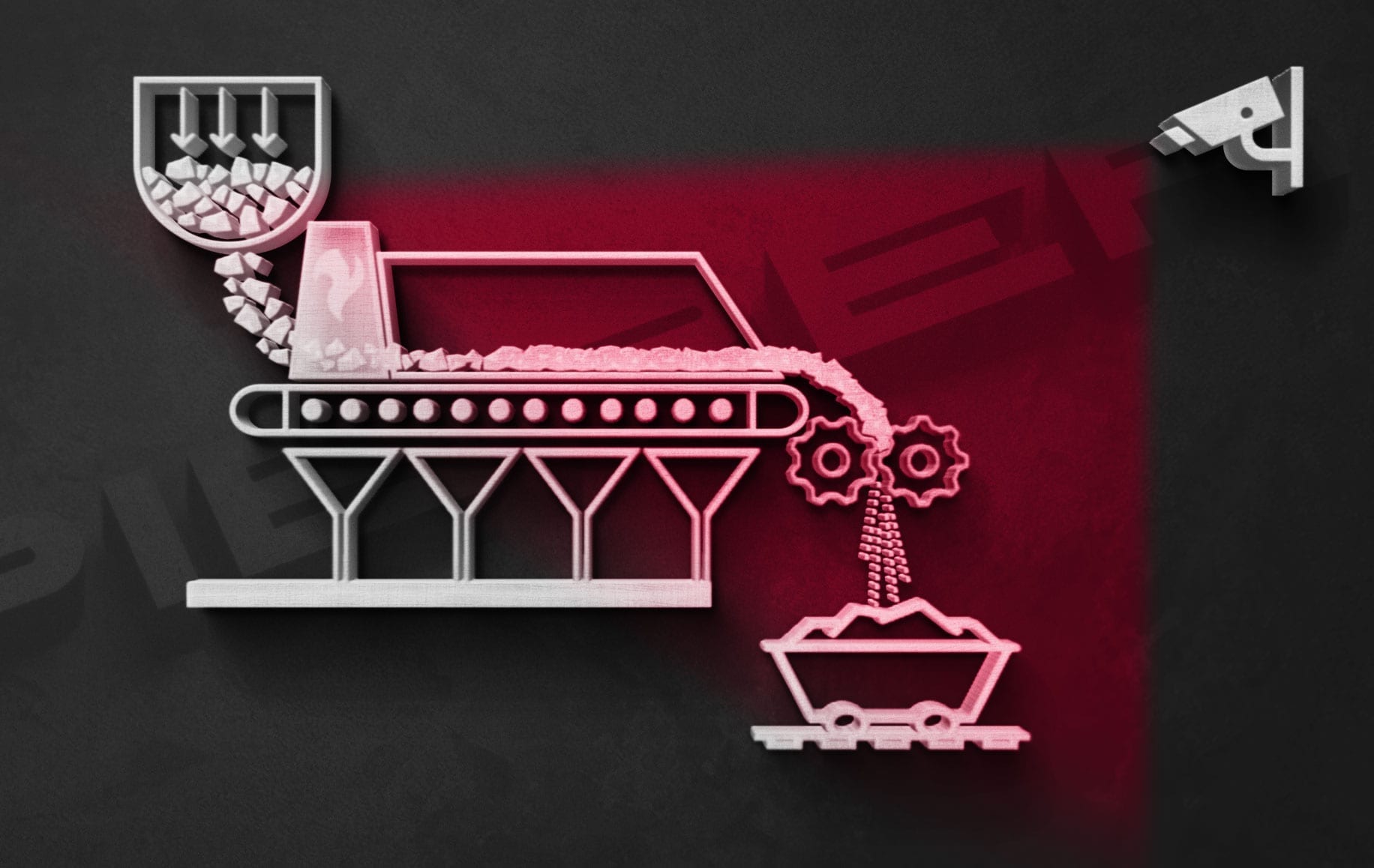

Sinter is considered an important basic material for the production of pig iron.

The production, among others from fine ore and coke, takes place in the sintering plant.

Since all materials must have a certain minimum size for further processing in the blast furnace, the raw materials are baked together by a firing process in the sintering plant. The resulting mass - the sinter cake - is fed into the blast furnace after further processing through crushers, coolers and screens.

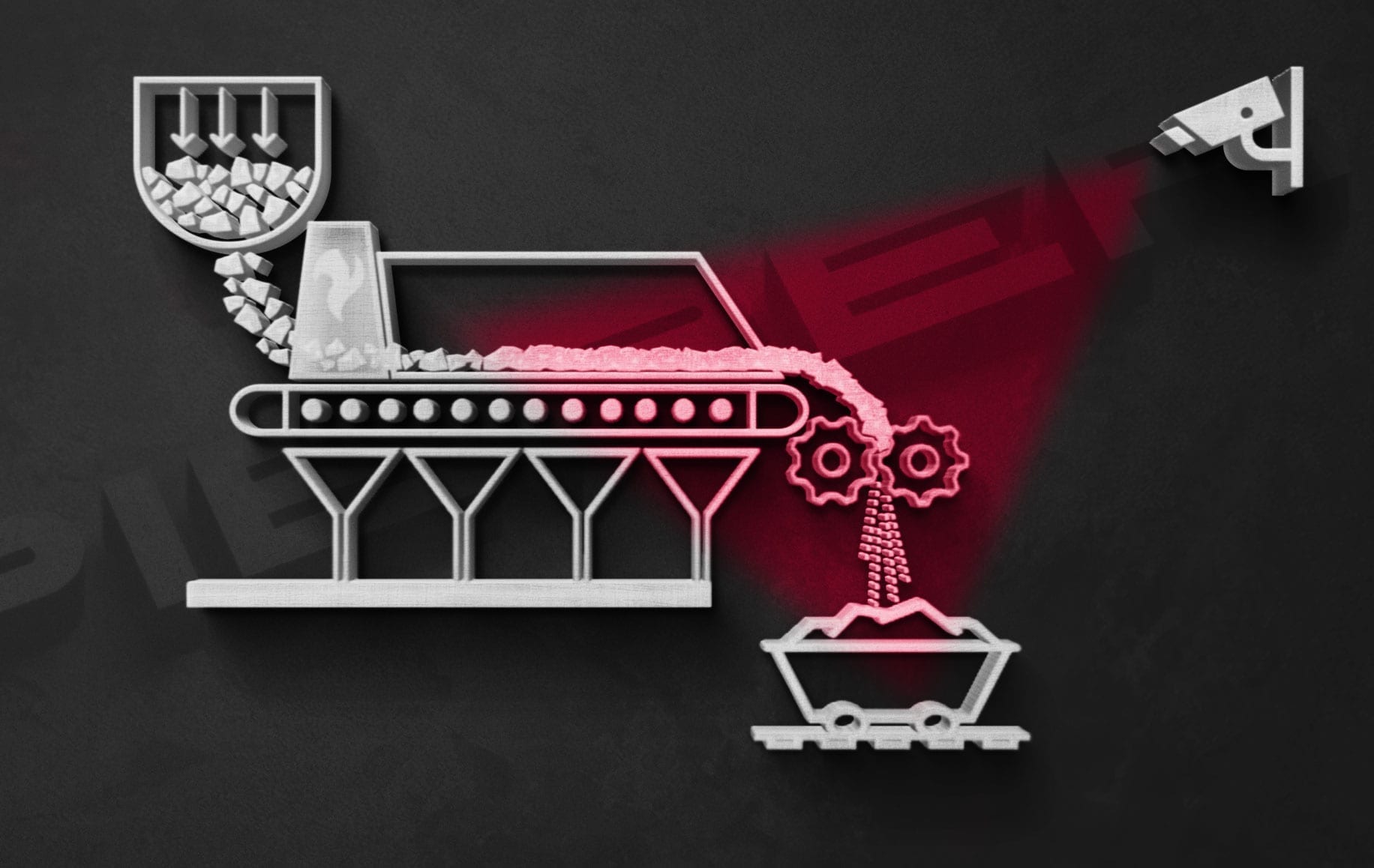

OVERVIEW CAMERAS

Process monitoring, which focuses on detailed monitoring and evaluation within a production chain, should not disregard visual observation of the complete plant. For this purpose, overview cameras are installed in such a way that they provide an overall picture of the running production. The images generated in this way reach the control centre via live stream so that emerging malfunctions can be detected at an early stage - so you always have an overview of everything!

In addition to avoiding cost-intensive production stoppages, the environment also benefits here: a defective filter system, for example, can be detected more quickly, as a change in the colour of the exhaust gas often already indicates this. The control room can thus take immediate action and counteract dangers.

At the same time, the use of overview cameras increases occupational safety for the skilled personnel working directly on the equipment: The early detection of a malfunction, which the employee on site may not even be able to perceive, reduces the risk of an accident to a minimum.

SINTER PREPARATION / CRUSHER

In order for the sinter produced after the firing process to be fed into the blast furnace, it must be processed directly in downstream plants. By baking the individual raw materials together, a flat, porous mass is created from the fine ore and coke as well as other auxiliary materials, which must be broken down to the required size by the crusher. To ensure that it breaks evenly, it is cooled during transport on the conveyor belt. A consistent temperature distribution is essential in this process.

The use of visual or thermographic cameras helps the operator to quickly detect deviations. If the sinter cake breaks irregularly or an undesired drop in temperature is measured, partial process heat can be added again via nozzles located on the underside of the conveyor belt.