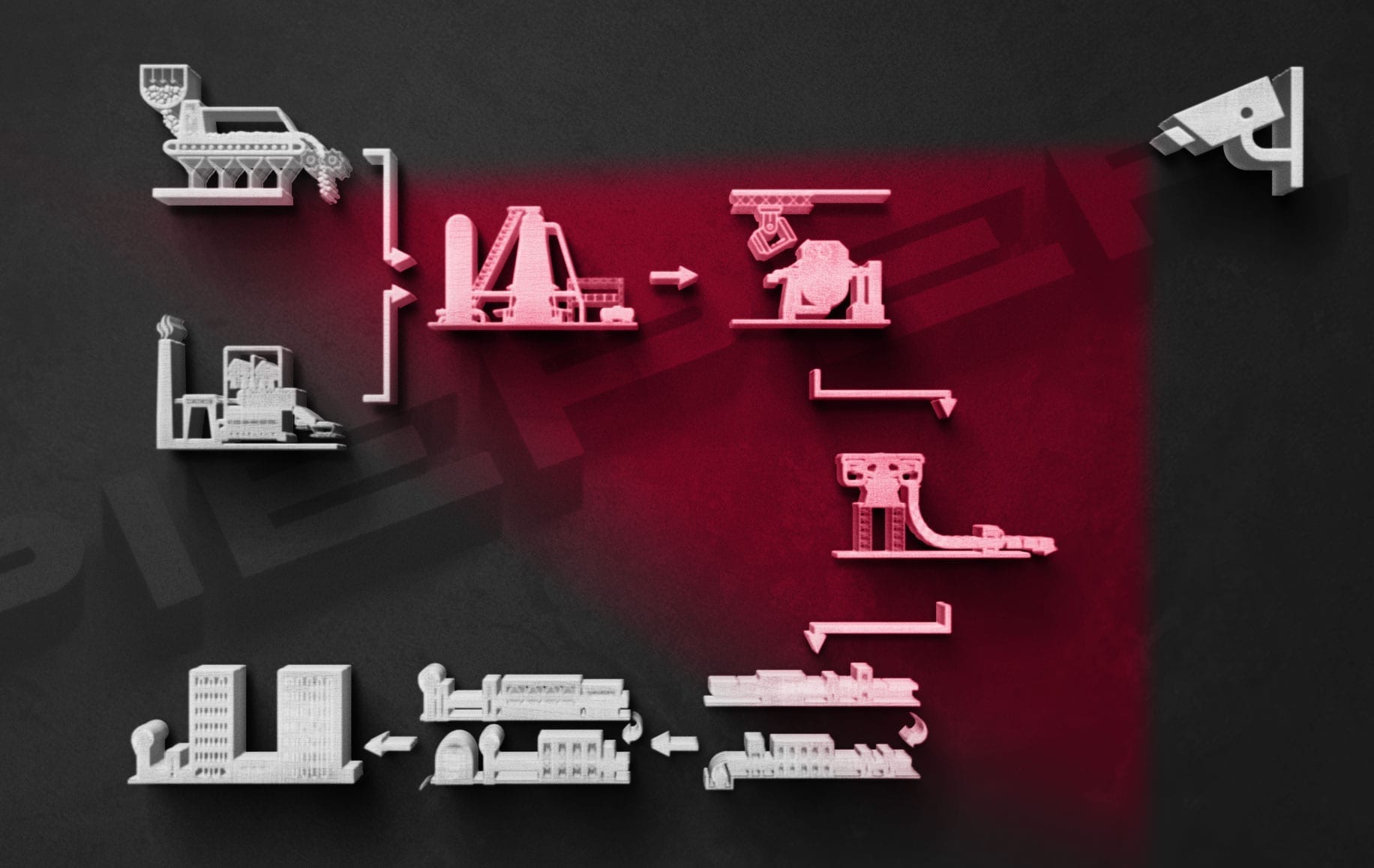

Networked and modern solutionsfor the steel industry

"Modern complete solutions through the eyes of our customers." - This is our claim when it comes to safe production processes in industry. Regardless of whether high temperatures, fire, dust or vibration: for more than 50 years, we have stood PIEPER for the development, production and installation of individual process monitoring solutions from experts.

As a reliable partner, we take care of your individual projects on site - before, during and after installation. A sound knowledge of the industry is only the beginning. Special challenges such as optimal utilisation of plant capacity, cost-efficient production, improved planning and logistics as well as increased safety for man and machine find their answer in our systems.

TRADITION MEETS MODERNITY

The steel industry has a long history. Proven production methods are still used today. But when the economic framework conditions change, a technology is needed that meets them adequately and in a modern way. In order to remain competitive, steelworks today must above all avoid a loss of efficiency and quality. Outdated plants make this task more difficult.

And this is exactly where the solutions from PIEPER come into play:

Digital, video surveillance-based and interconnected process monitoring systems ensure a smooth production chain. In combination with appropriate management and analysis software and taking into account all the conditions on site, the advantages are obvious:

- Efficiency: Integration of digital video technology into already existing systems

- Overview: Provision of an overall picture of the running production as well as live images for monitoring individual processes

- Hazard minimisation: Avoidance of cost-intensive production downtimes

- Safety: Central control away from the high-temperature environment

- Resource optimization: Planning of maintenance intervals and repairs

- Quality: Analysis and evaluation possibilities of material and machine

- Flexibility: Use of special camera technology depending on the environment (visual, thermographic, sensor-based)

- Sustainability: Documentation and logging support

The result for modern steel production:

Significant process acceleration through automation