Hot-dip galvanising protects the steel from weathering and corrosion.

In strip galvanizing, the coils are unwound and joined into a continuous strip with the help of a welding machine. After the sheet has been heated in a continuous furnace, the actual zinc treatment takes place in a melting bath. During this production step, strip speeds of up to 220 metres per minute are achieved before the steel strip is wound into coils again.

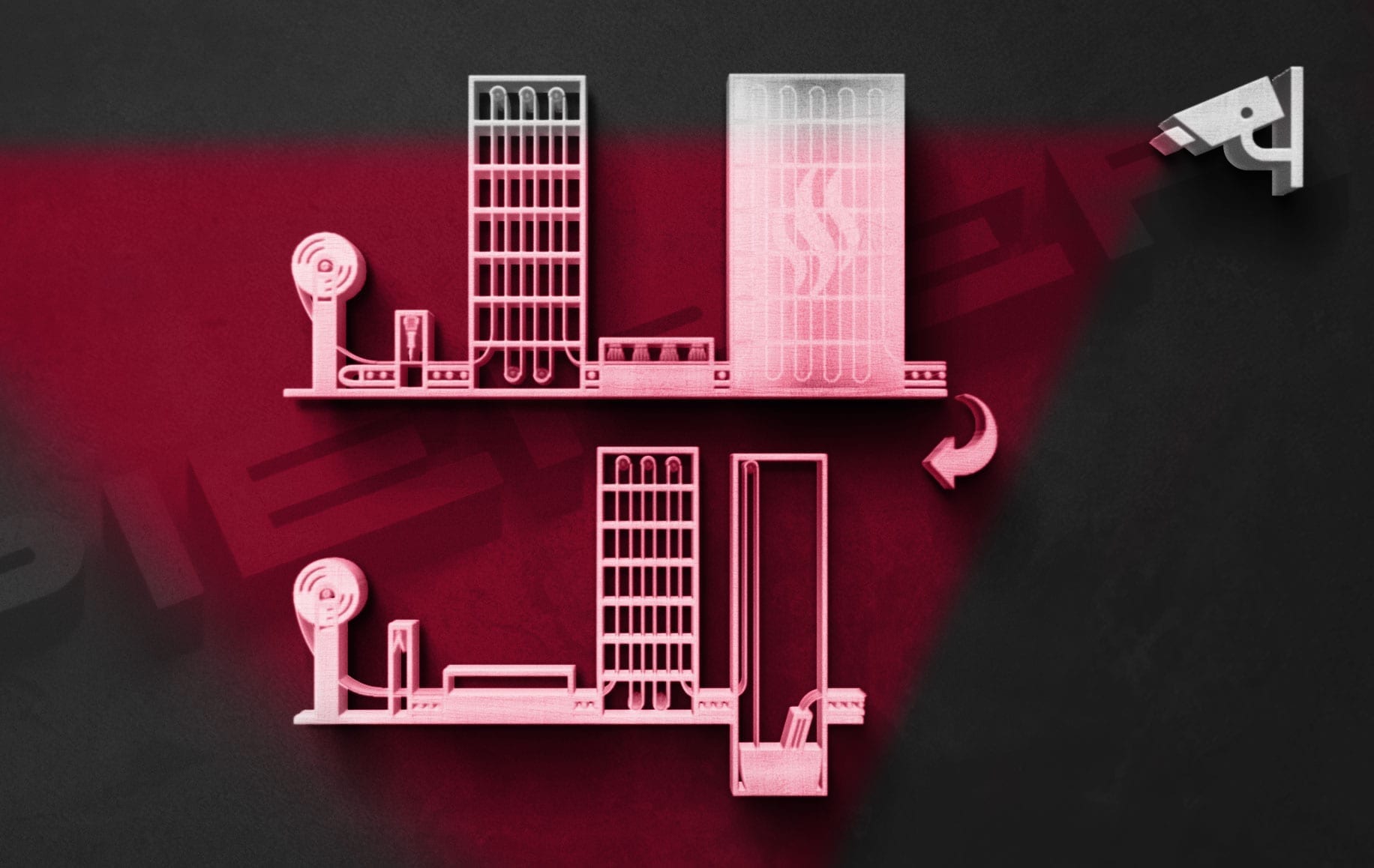

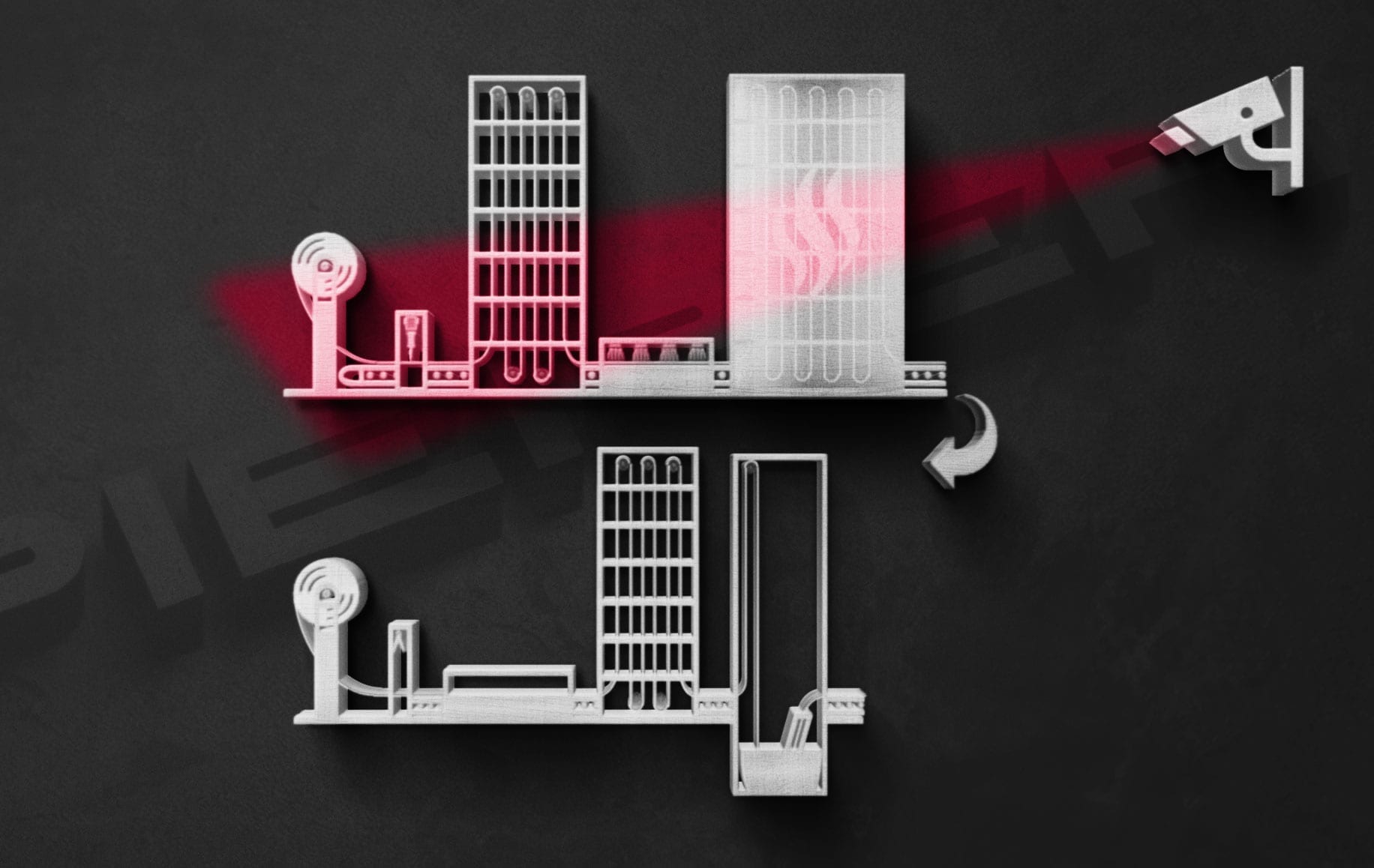

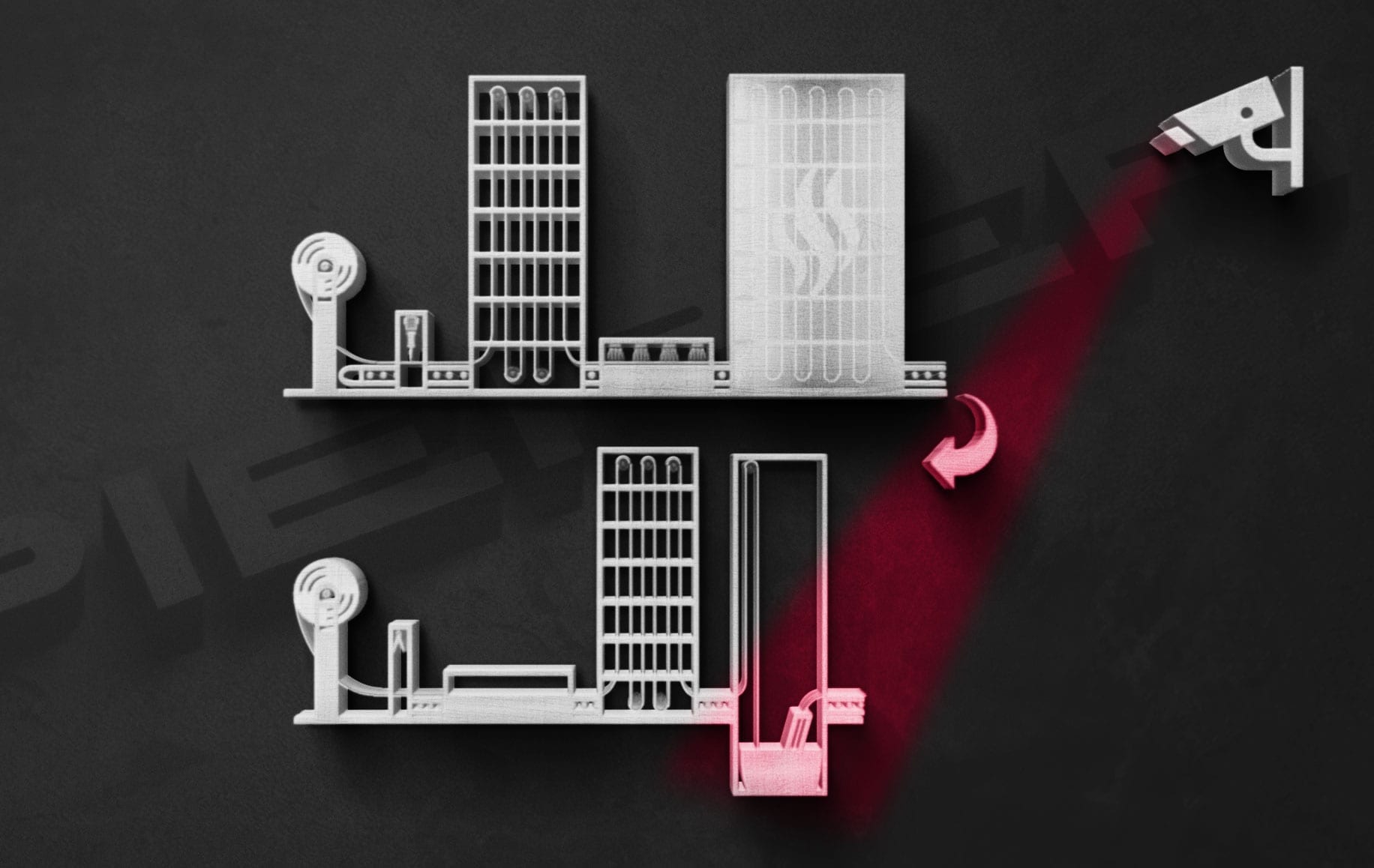

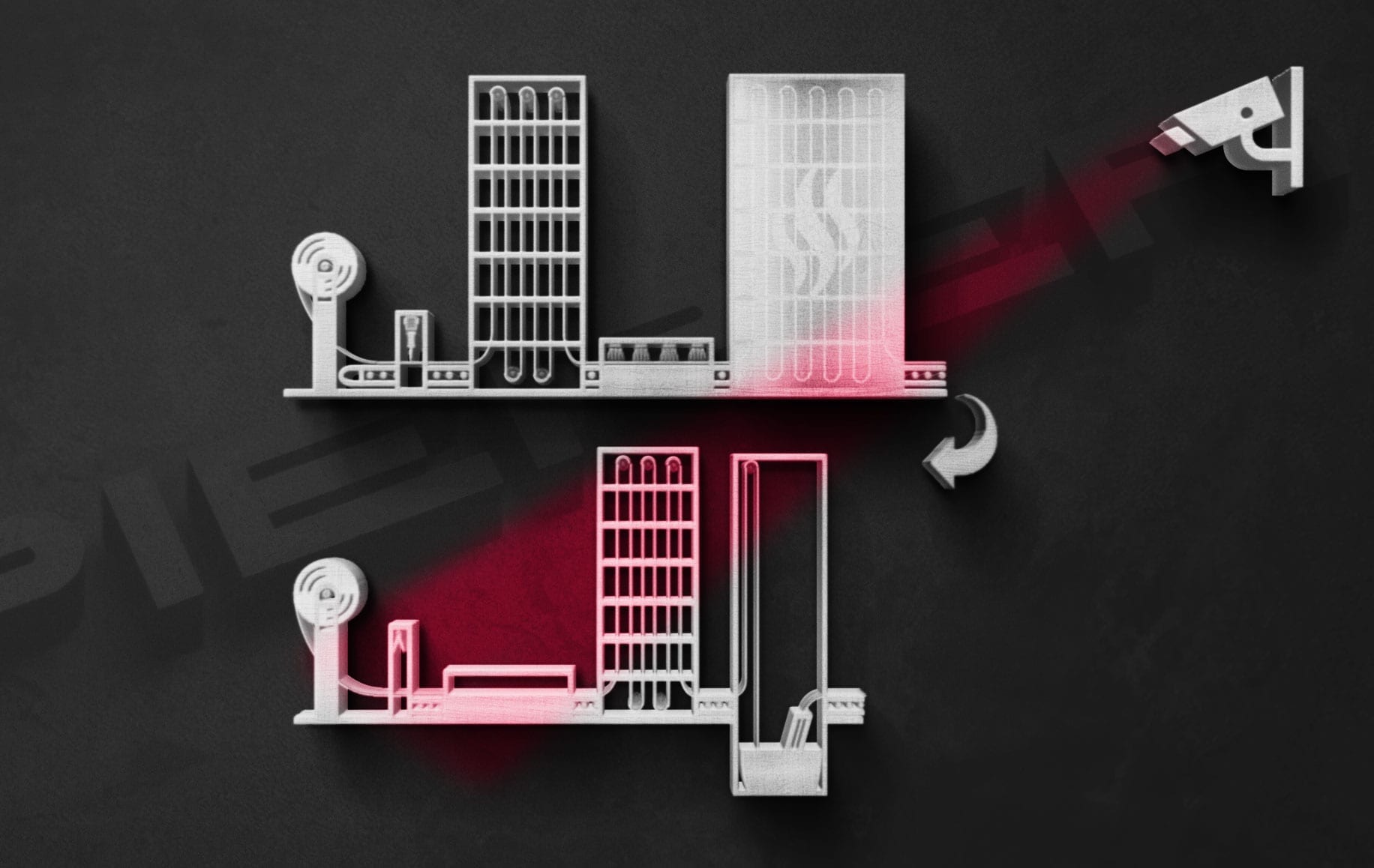

OVERVIEW CAMERAS

Process monitoring, which focuses on detailed monitoring and evaluation within a production chain, should not disregard visual observation of the complete plant. For this purpose, overview cameras are installed in such a way that they provide an overall picture of the running production. The images generated in this way reach the control centre via live stream, so that emerging malfunctions can be detected at an early stage and an overview of the entire plant is always available.

In addition to avoiding cost-intensive production stoppages, the environment also benefits here: a defective filter system, for example, can be detected more quickly, as a change in the colour of the exhaust gas often already indicates this. The control room can thus take immediate action and counteract dangers.

At the same time, the use of overview cameras increases occupational safety for the skilled personnel working directly on the equipment: The early detection of a malfunction, which the employee on site may not even be able to perceive, reduces the risk of an accident to a minimum.

PRE-CONTROL / WELDING MACHINE

Already during the decoiling process, the sliver is checked for gross defects with the support of visual cameras.

The product is then joined together in the welding machine to form a continuous strip. The clean execution of the welding process is also checked with the help of visual cameras.

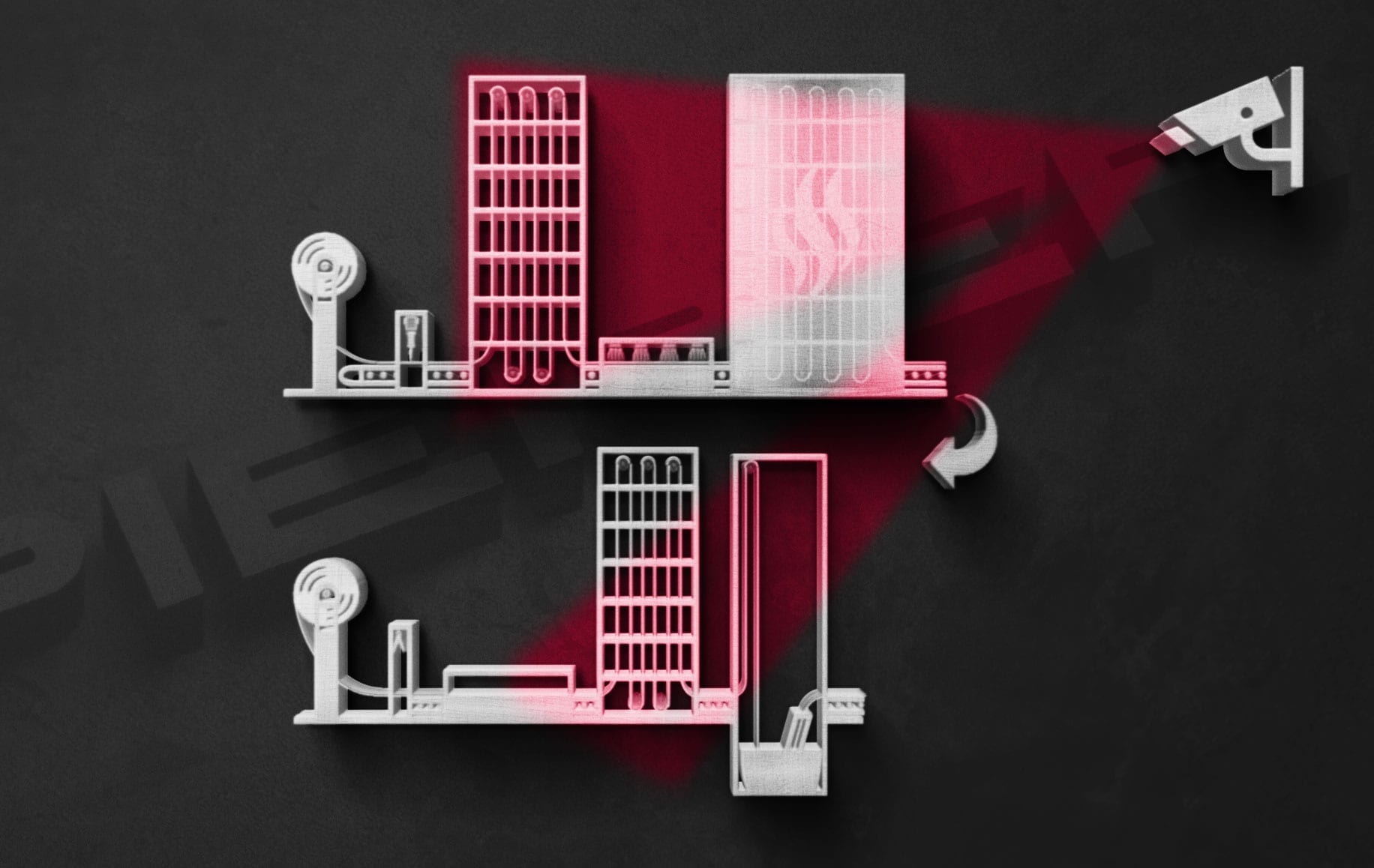

ENTRY AND EXIT-SIDE LOOPER

The entry and exit-side loopers are used to store the strip during the welding process and for the cutting machine before the galvanized product is wound into coils again. Visual cameras are used to check that the sheet does not jam or break off and thus jeopardize the continuous production process.

ANNEALING FURNACE

Before the steel can bond with the zinc layer, it is heated to approx. 450 °C to 650 °C in a pre-annealing or continuous furnace. During this process, furnace probes are used to continuously observe the strip position. In addition, due to the poor lighting conditions, external lighting is used, which is either already integrated into a probe or placed separately in the furnace as a light probe.

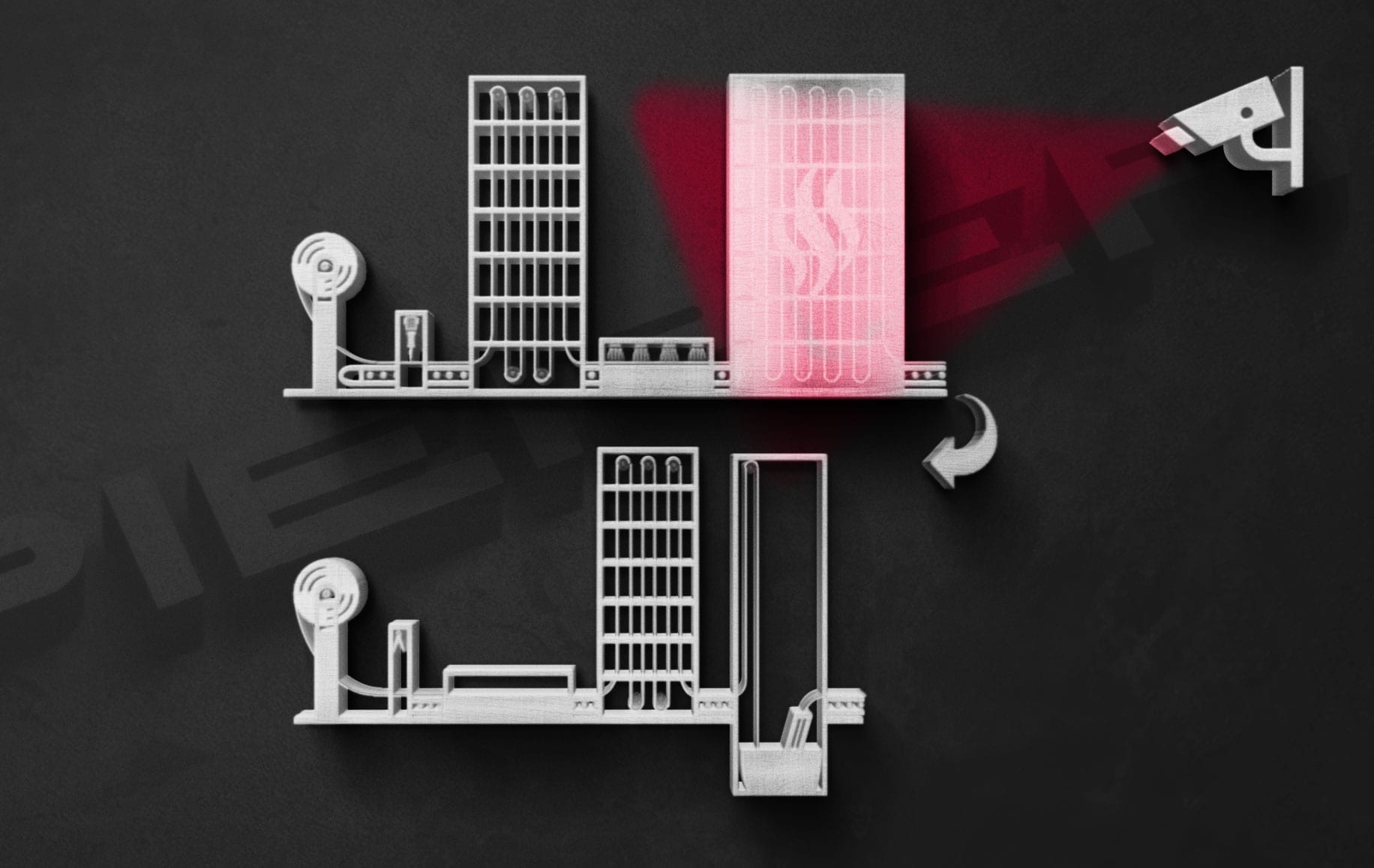

GALVANIZING BATH

The strip is fed into the galvanizing bath via a sluice, the so-called nozzle. In order for the steel to bond with the zinc, the material is heated to a temperature comparable to that of the galvanizing bath under inert gas and vacuum.

Since slag can form during this process, the belt inlet is monitored by special furnace probes. As with the annealing furnace, the lighting conditions here are also very poor, so external lighting has to be used.

INSPECTION

After leaving the galvanizing bath, an initial surface inspection is carried out using visual cameras. After the subsequent layer thickness measurement, the strip is still passed over inspection tables where employees carry out a visual inspection; to support quality assurance, the process can additionally be observed with visual cameras.

At the end of this process, the hot-dip galvanising protects the steel strip from possible weathering and thus also from corrosion.