Thermographic and visual condition monitoring for trouble-free operation in the converter

In secondary metallurgy, up to 400 tonnes of crude steel can be cooked in a modern converter. For this purpose, liquid pig iron, steel scrap and slag binder are fed into the plant in the first step - freshening. Only in the further course is the desired steel quality achieved by adding alloying elements, adjusting the carbon content and removing accompanying elements. When the crude steel is subsequently poured into ladles, the slag produced is retained and transported on to the continuous casting plant.

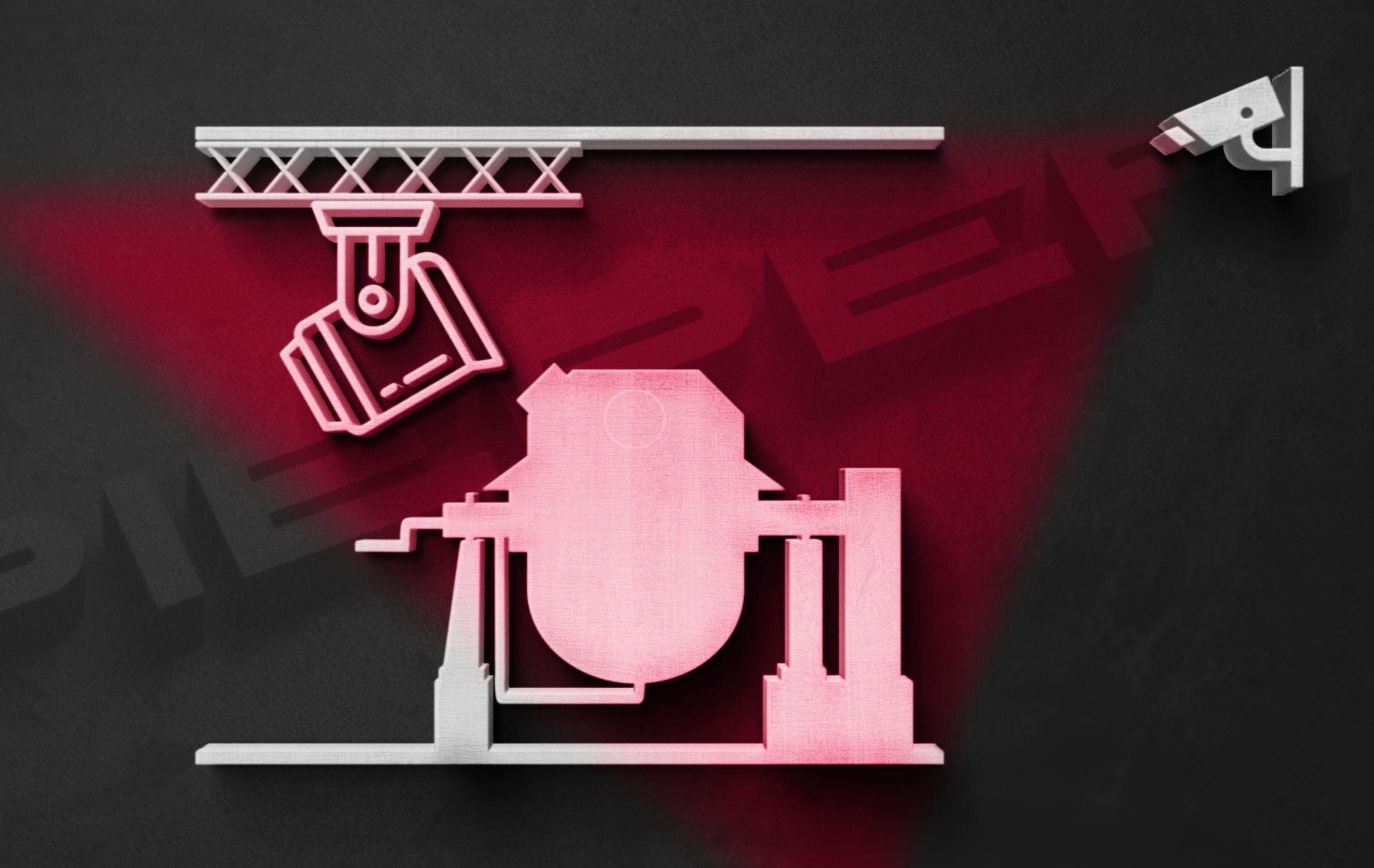

OVERVIEW CAMERAS

Process monitoring, which focuses on detailed monitoring and evaluation within a production chain, should not disregard visual observation of the complete plant. For this purpose, overview cameras are installed in such a way that they provide an overall picture of the running production. The images generated in this way reach the control centre via live stream, so that incipient malfunctions can be detected at an early stage.

In addition to avoiding cost-intensive production stoppages, the environment also benefits here: a defective filter system, for example, can be detected more quickly, as a change in the colour of the exhaust gas often already indicates this. The control room can thus take immediate action and counteract dangers.

At the same time, the use of overview cameras increases occupational safety for the skilled personnel working directly on the equipment: The early detection of a malfunction, which the employee on site may not even be able to perceive, reduces the risk of an accident to a minimum.

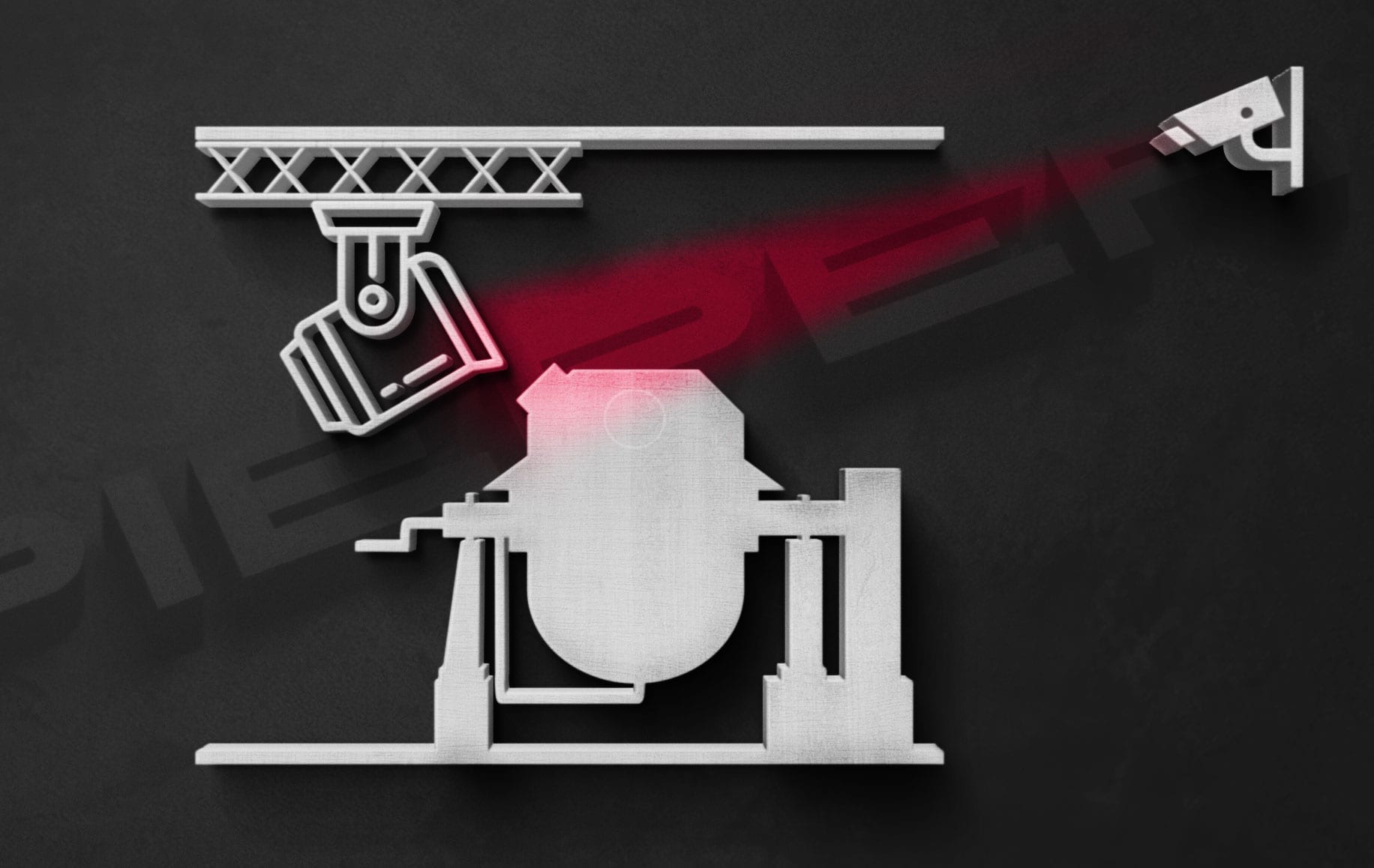

LEVEL DETECTION / SLAG DETECTION

The requirements for the degree of purity of steel are continuously increasing. Thermographic or visual observation of the transfer of pig iron into a converter significantly facilitates the detection of slag parts - thanks to different radiation characteristics of slag and pig iron at the same temperature.

LADLE INSPECTION

A ladle that continuously transports liquid crude steel from the converter to the continuous casting furnace is subject to high material demands; accordingly, it must be maintained and repaired frequently. Thermographic condition monitoring of the l adle helps the operator to determine maintenance intervals precisely.

In addition to strain and wear of the refractory lining, dangerous hot spots are also detected thermographically in time before the ladle can break.

Without the support of cameras, the operator has to estimate the maintenance and repair interval and take a ladle out of operation at correspondingly short intervals to avoid accidents, resulting in inefficient production times.

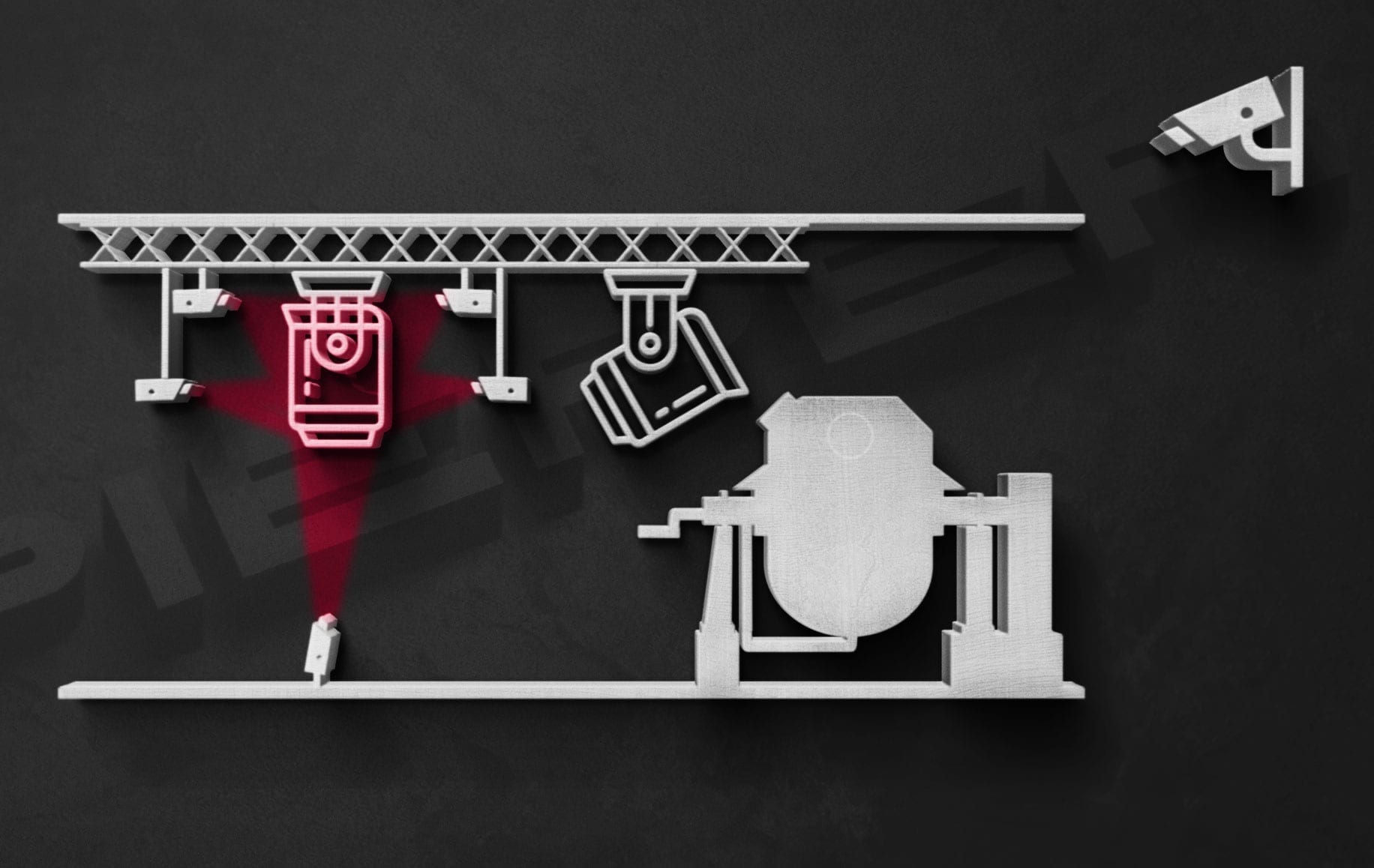

MAINTENANCE AND REPAIR OF LADLES

Due to the high heat load, casting ladles must be regularly maintained and repaired. Robots are usually used for this purpose, which ensure that the refractory lining is sprayed out evenly. For quality assurance of the ladle condition, a furnace probe is used to observe the process in detail.

If repairs are necessary, the refractory lining must be renewed. To reduce the potential danger and speed up the process, spraying robots are now used to take over this work.

Supported by visual cameras and external lighting that provide a 360° view, the robot is controlled by an external operator. In this way, the new lining can be applied evenly in a short time and the pouring ladle can be used again more quickly.

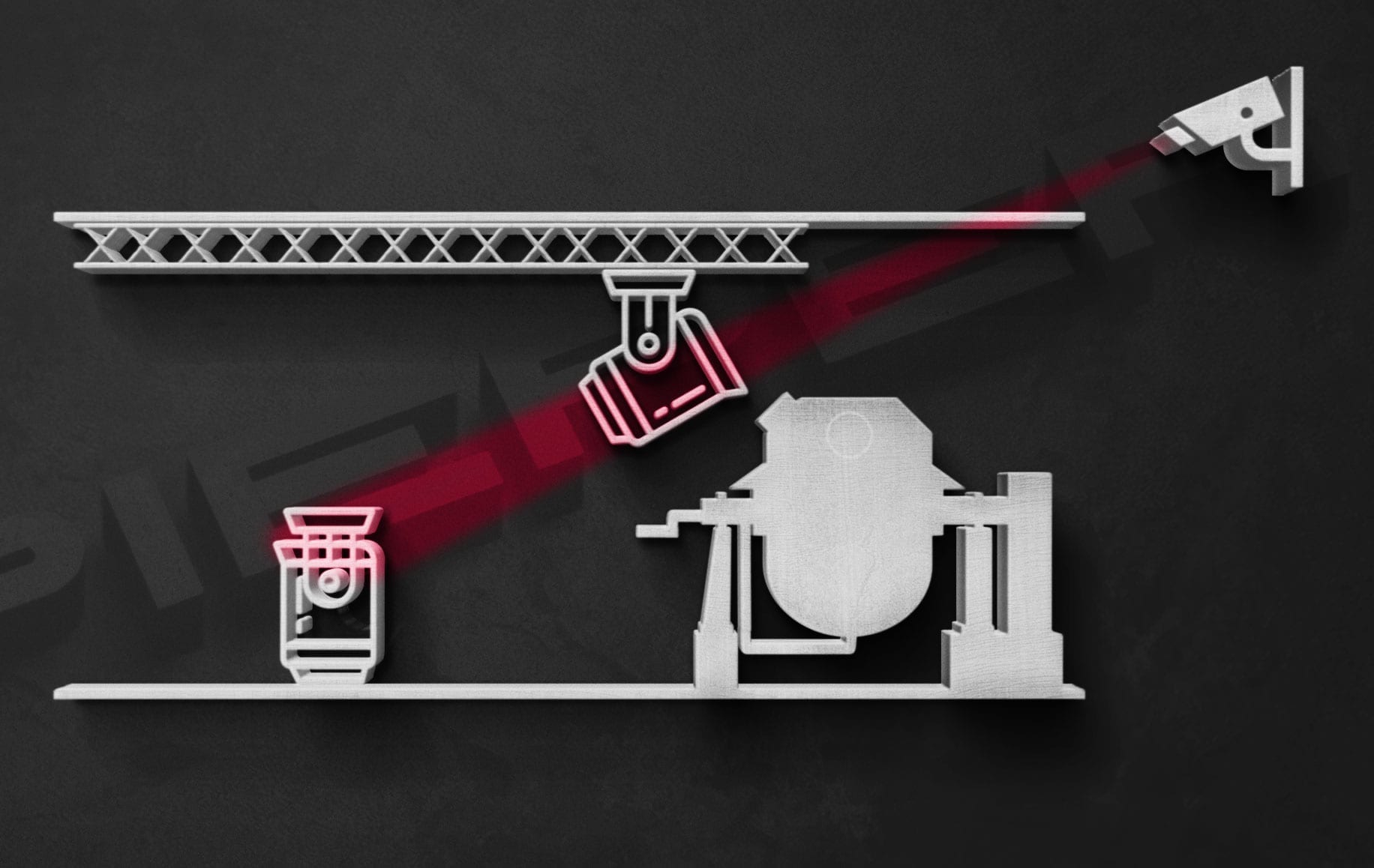

POSITION OBSERVATION "SAND FILLING"

In steel casting, stopper ladles are often used that have a slide on the underside to drain liquid crude steel into the continuous casting furnace. These ladles must always be refilled with a certain amount of sand before filling to prevent the slide from caking on the lower part of the ladle due to the crude steel and no longer being able to be opened.

However, if too much sand is used, it solidifies and the slide has to be opened manually by an employee. This not only leads to delays, but also poses a great risk of accidents due to working on a hot, filled pouring ladle.

By using a camera to monitor the sand level, delays are reduced and potential hazards minimised to ensure a largely trouble-free process.

VACUUM FURNACE

After the crude steel leaves the converter, it can optionally be further treated in a vacuum furnace to increase the material quality. In this process, gases in the crude steel, such as sulphur or phosphorus, are dissolved or alloys are added.

Depending on the method used, overview cameras or furnace probes are used for process monitoring.