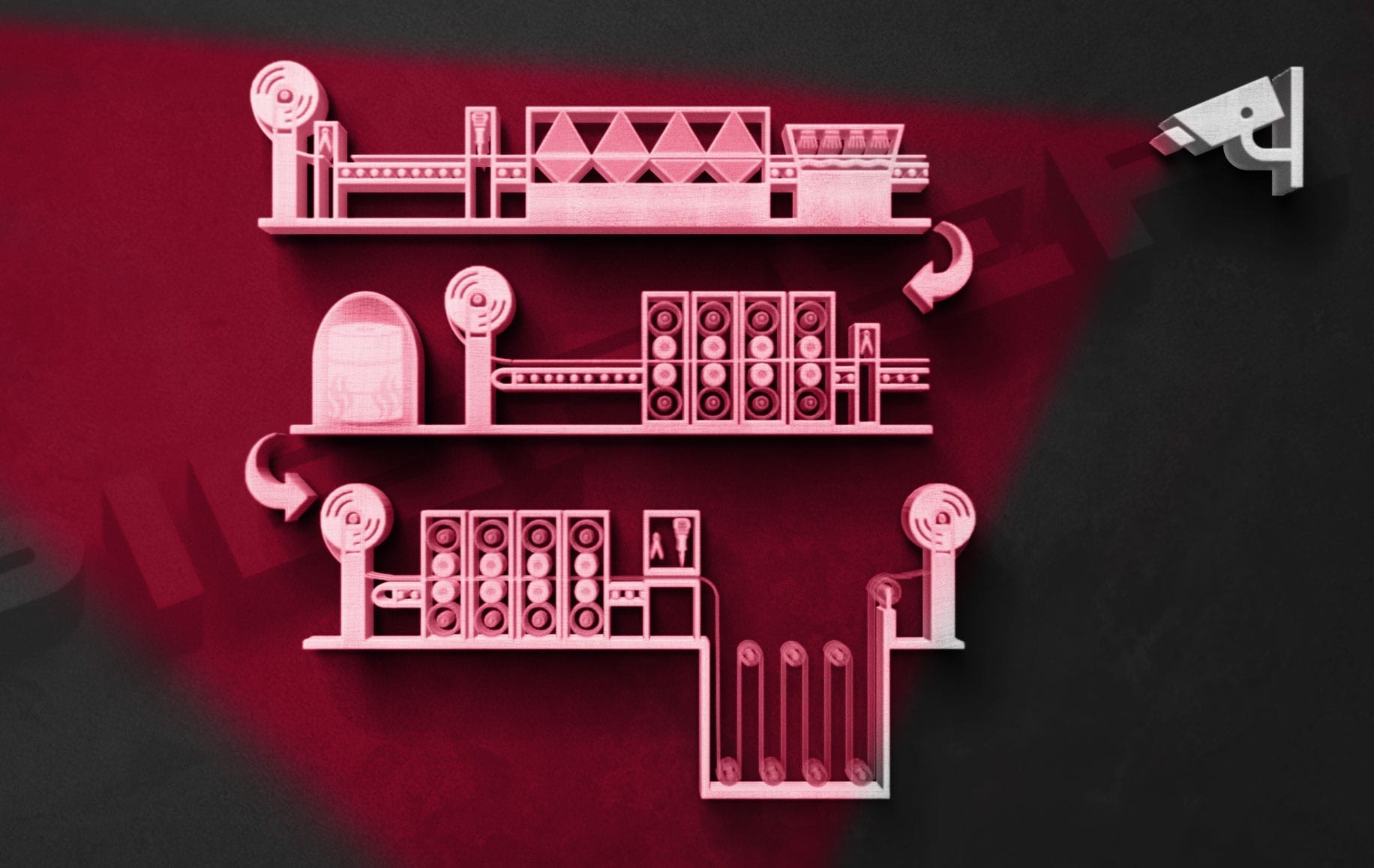

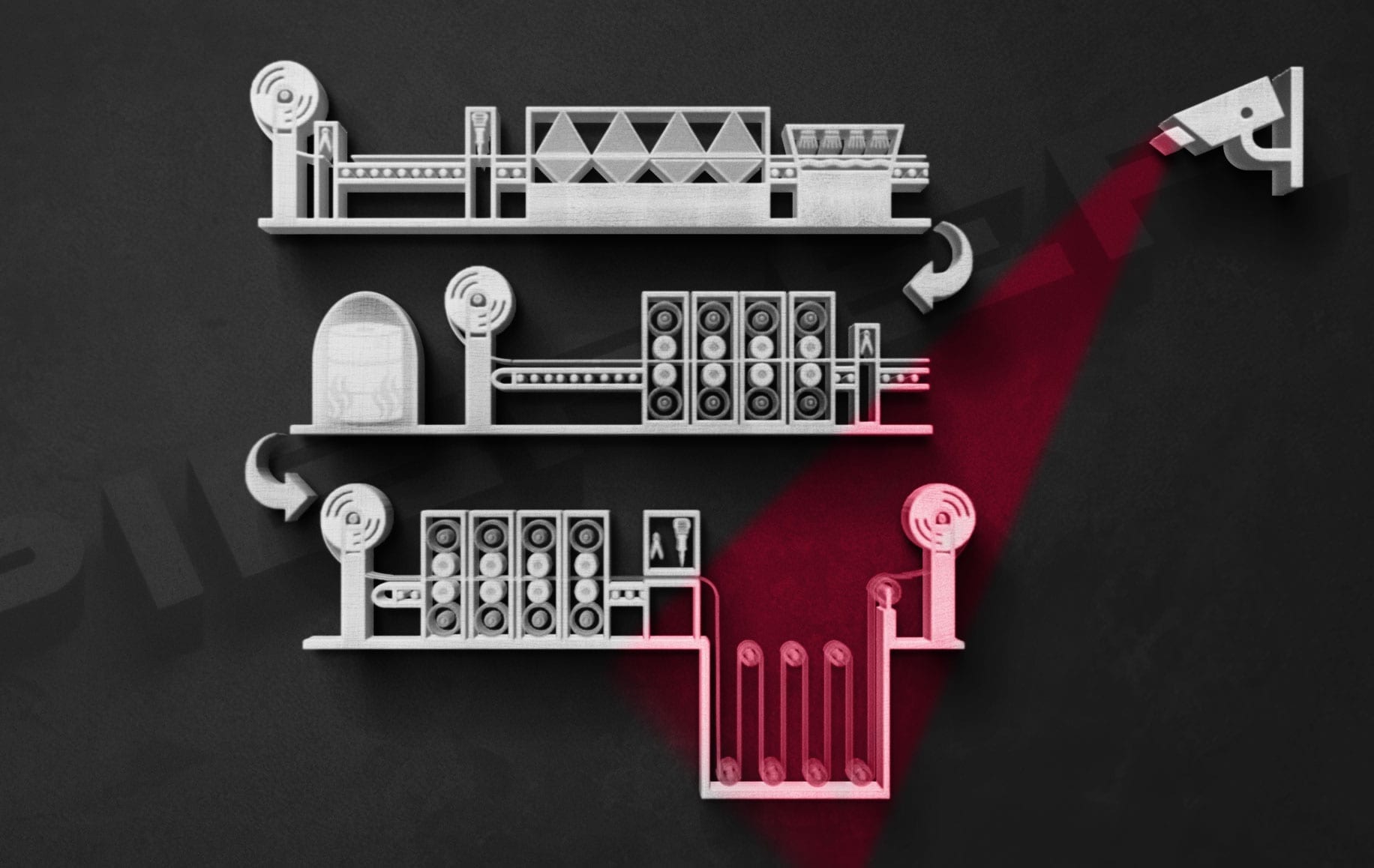

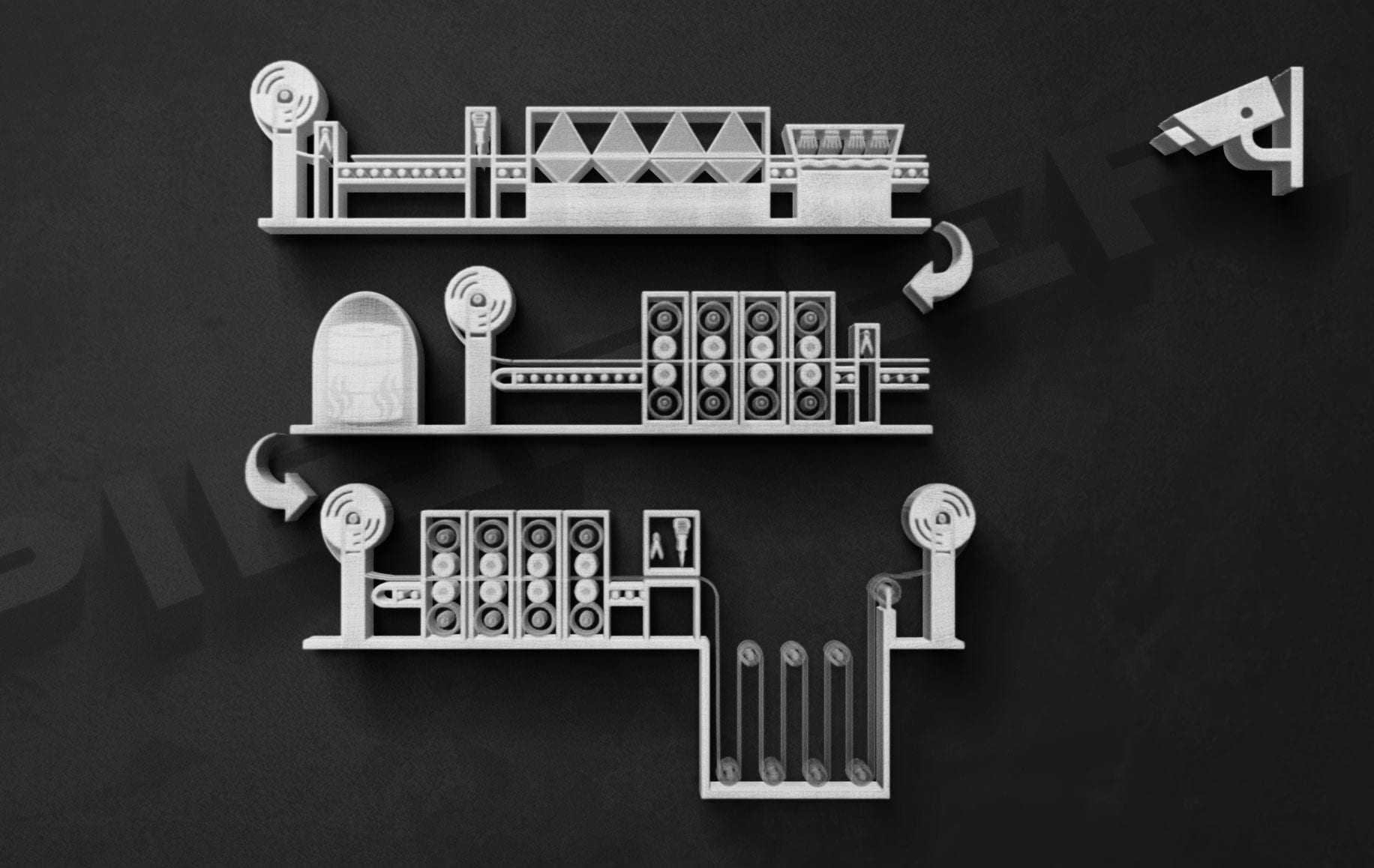

The rolling process in the cold rolling mill

In order to reduce the steel strip down to thicknesses of only 0.25 to 0.3 mm, the strip is first freed from any adhering scale in the continuous pickling line. Rolled into coils again, the steel is heated in the bell annealer. During the actual rolling process, the steel is given its final material properties. Afterwards, the cold strip is automatically split lengthwise and/or crosswise in the slitting line so that it can then be packed for shipping.

OVERVIEW CAMERAS

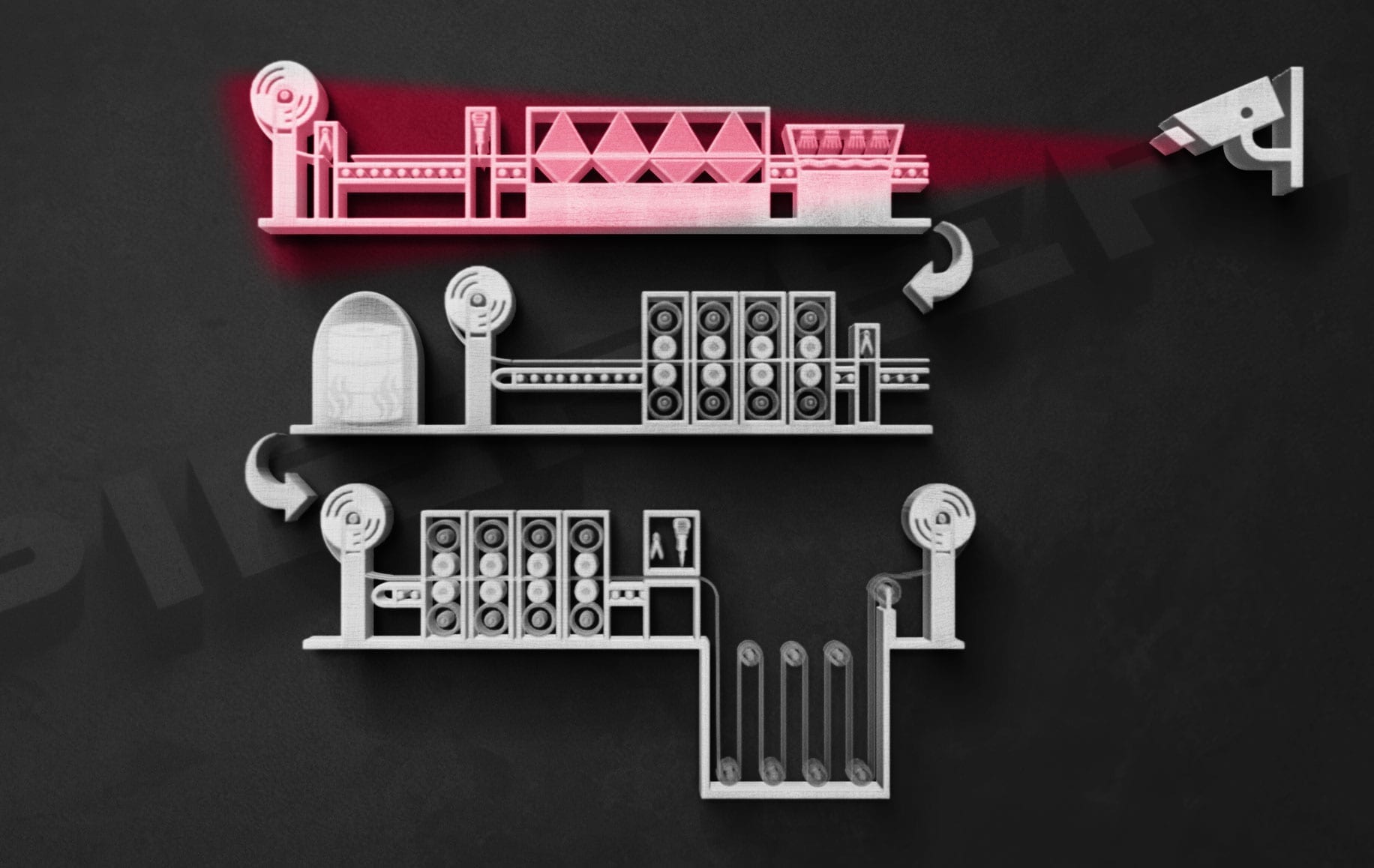

Process monitoring, which focuses on detailed monitoring and evaluation within a production chain, should not disregard visual observation of the complete plant. For this purpose, overview cameras are installed in such a way that they provide an overall picture of the running production. The images generated in this way reach the control centre via live stream, so that incipient malfunctions can be detected at an early stage.

In addition to avoiding cost-intensive production stoppages, the environment also benefits here: a defective filter system, for example, can be detected more quickly, as a change in the colour of the exhaust gas often already indicates this. The control room can thus take immediate action and counteract dangers.

At the same time, the use of overview cameras increases occupational safety for the skilled personnel working directly on the equipment: The early detection of a malfunction, which the employee on site may not even be able to perceive, reduces the risk of an accident to a minimum.

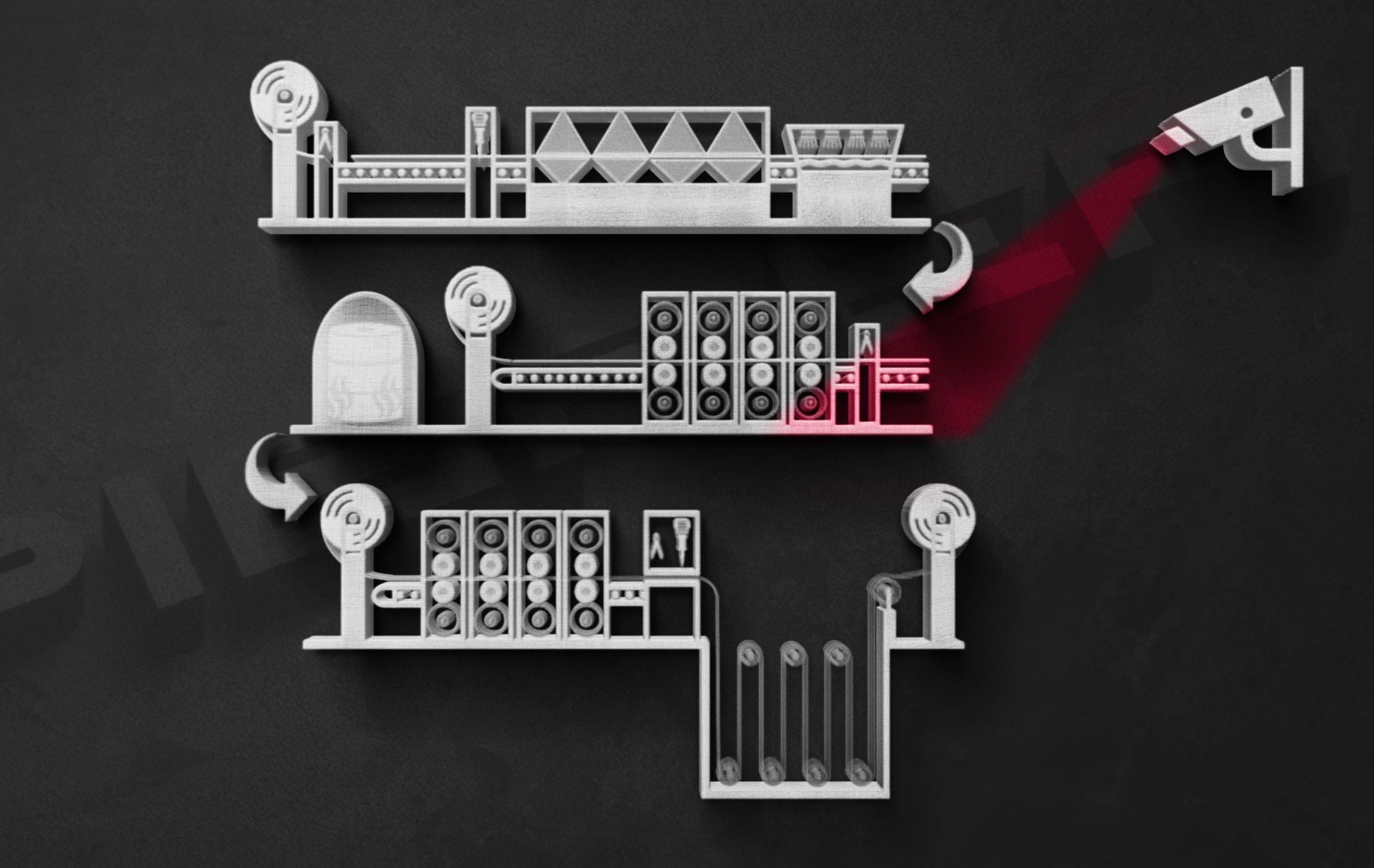

PRE-CONTROL INLET AREA PICKLING / CONTINUOUS PICKLING LINE

In order to exclude possible material defects, a visual pre-inspection of the material is already carried out in the inlet area of the continuous pickling line when the coils are uncoiled. This important quality assurance process can be supported by visual cameras.

When uncoiling, the ends of each coil are first cut off with the cropping shears to obtain even end edges. The product is then joined together in the welding machine to form a continuous strip. The clean execution of the welding process is checked with the help of visual cameras.

QUALITY ASSURANCE PICKLING LINE

After removal of the oxide layer (scale), rinsing and drying of the belt, a visual material check is carried out again for quality assurance, which can be supported by visual cameras.

The trimming cut, which removes protruding edges of the strip before it enters the tandem mill, is also monitored with the support of visual cameras. This simplifies the manual correction of the strip run for the operator before it is fed into the tandem mill, and thus to the first rolling process.

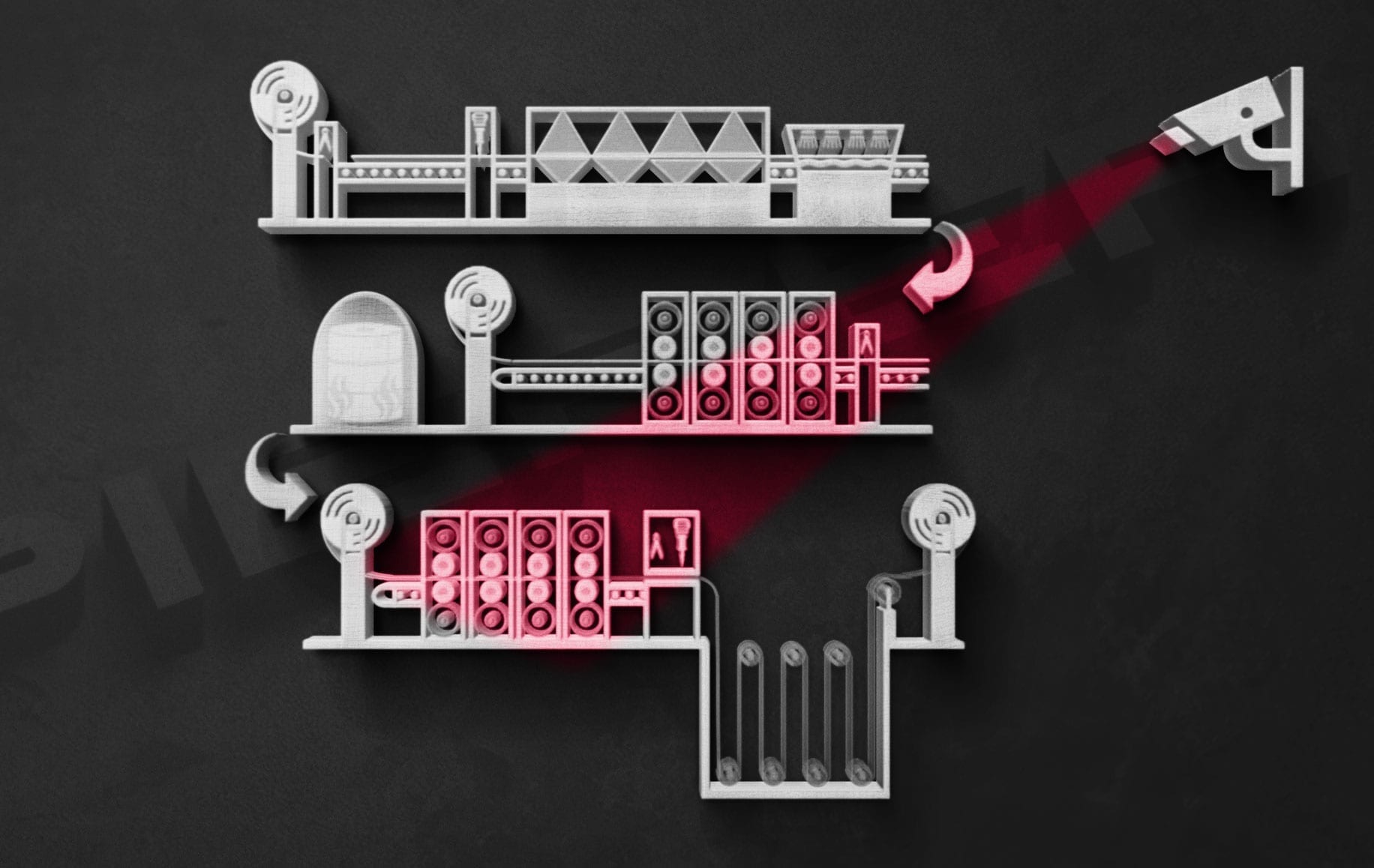

QUALITY ASSURANCE ROLLING ROADS

In both a tandem mill and a skin-pass mill, the endless strip is guided through several rolls lined up in a row. In these processes, the cold strip is given its required properties such as thickness or surface finish, whereby the rolling lines can be adapted according to the customer's order.

Since the rolls are generally exposed to high stresses due to heat and vibration, there is a certain potential for defects in the rolls and/or the material. To ensure that this can be noticed and rectified as quickly as possible, the rolling processes are monitored with the help of visual cameras.

In addition to visual inspection, the strip can also be monitored with special line scan cameras for quality assurance. Although the installation is more cost-intensive, it can make sense if the material is subject to high demands, as line-scan cameras offer the advantage of detecting irregularities in the material properties even at very high belt speeds.

LOOPING PIT / STRIP ACCUMULATOR

In some cold rolling mills looping pits or strip accumulators are used. Since the strip speeds can be very high and the different strips are wound into coils again after splitting, such devices for length compensation are needed to avoid material jams.

Visual cameras are used to check that the sheet metal, which is now very thin due to the machining process, does not tilt or break off and thus jeopardize the continuous production flow.